Brewing West Virginia's Beer

WHERE CRAFT MEETS COMMUNITY IN MORGANTOWN, WV

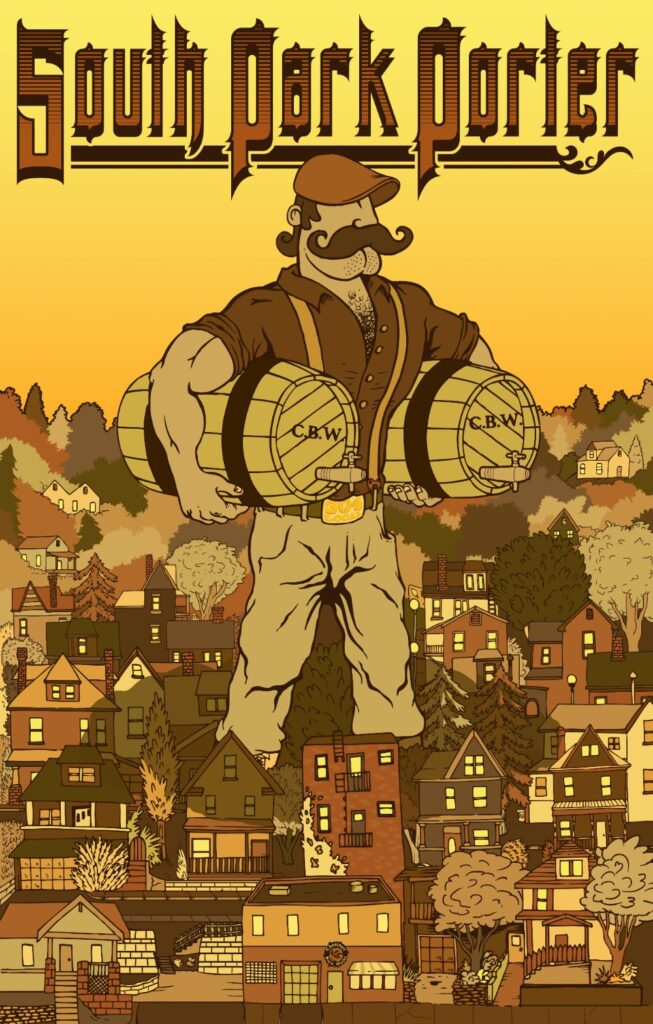

Flagship and seasonal crafts

We put our hearts into every batch.

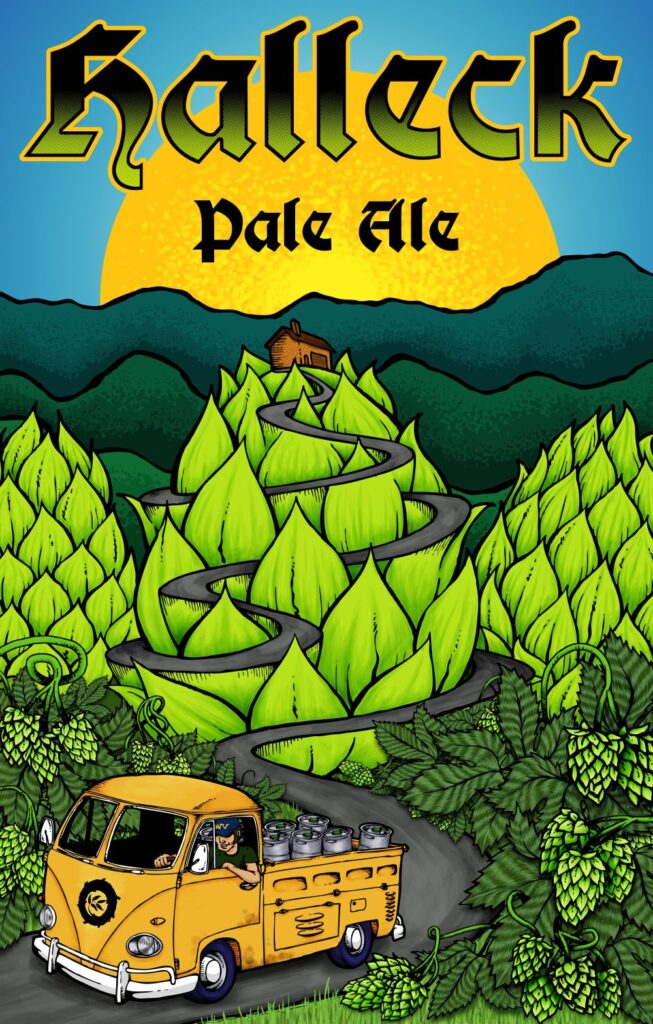

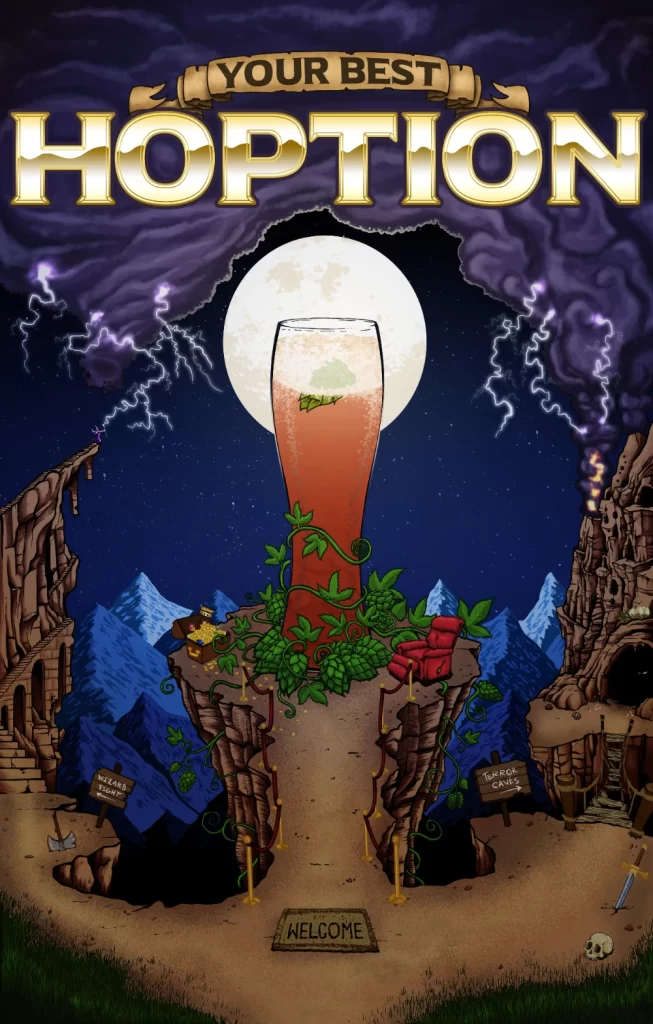

Whether you’re enjoying our long-time stars like Halleck Pale Ale or Your Best Hoption, or sipping our seasonal sours like the Salted Lime Gose or the Bloob, every beer is hand-crafted with care.

WE MAKE GOOD BEER

(And we try to do other stuff really well, too.)

Award-Winning

"Best of the Fest" Winner

2022 Hops on the Mon

Community First

Chestnut partners with local artists, craftsmen, farmers and small businesses.

Green & Clean

We salvage wood, repurpose spent grain and stay sustainable wherever we can.

0

+

Locations in WV

0

+

Happy Customers on UNTAPPD

0

+

Beer Awards